Teaching

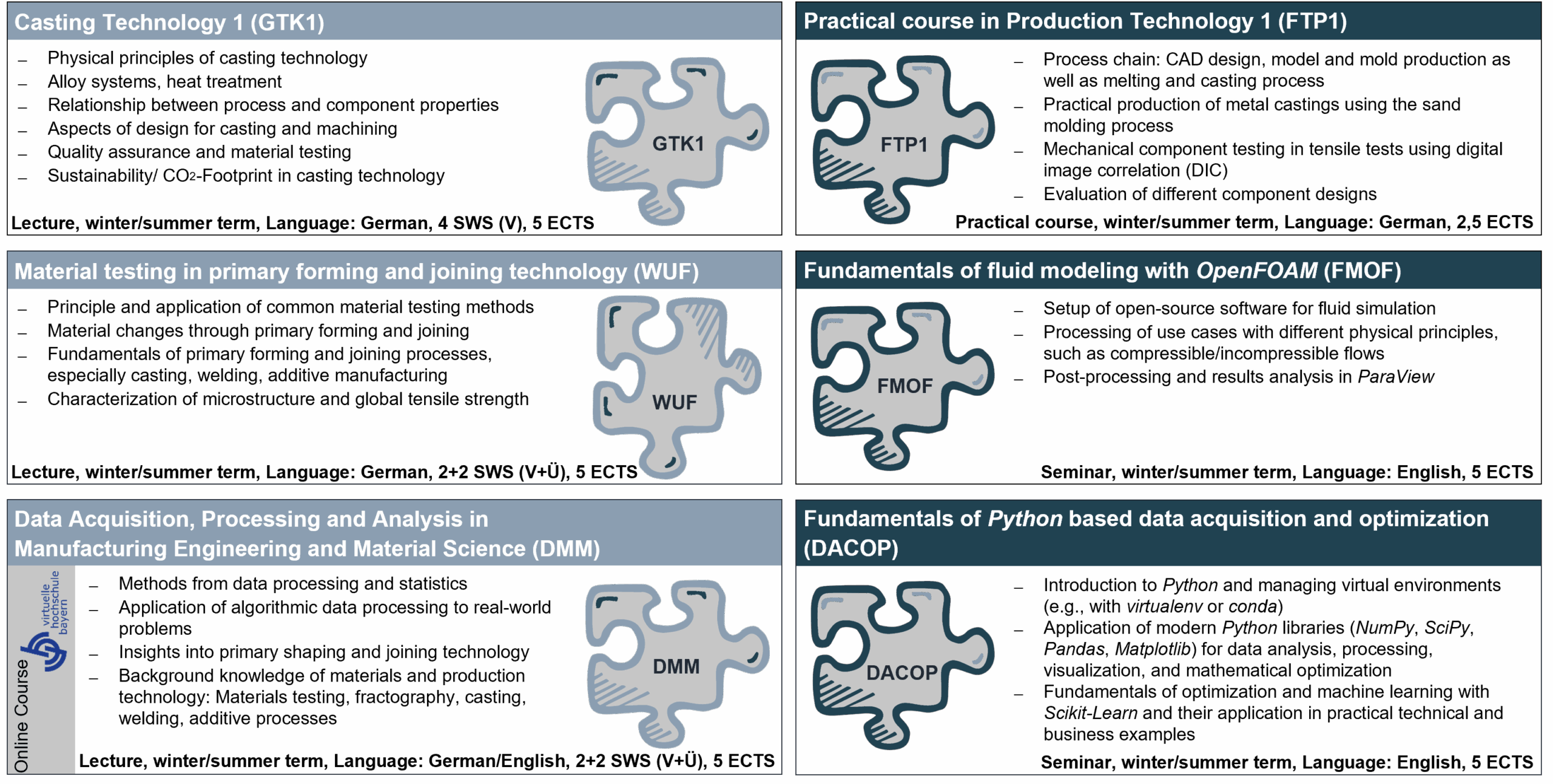

Our teaching portfolio combines classical foundry technology with modern knowledge in data analysis, simulation, and testing methods. All courses are coordinated in such a way that:

- Technical fundamentals (processes, materials, sustainability),

- Practical skills and laboratory experience, and

- Digital analysis and optimization competencies

are systematically structured and can be flexibly combined. We also emphasize the high transferability of learned methods to other engineering disciplines.

The lecture GTK1 serves as the foundational course, covering the physical, materials science, and design fundamentals of casting.

Students who wish to deepen their understanding of material characterization discussed in GTK1 can attend the WUF lecture. This course focuses on microstructural changes resulting from processes like casting, welding, and additive manufacturing. Numerous case studies facilitate the transfer of knowledge to research and industrial applications.

The VHB lecture DMM (a purely online course offered by the Virtual University of Bavaria) provides fundamental concepts of statistics, probability distributions, and optimization methods, which are practically applied using engineering datasets. Advanced techniques such as cluster and principal component analysis, as well as methods for evaluating measurement results (e.g., ANOVA, digital image correlation), complement the course content. The course explicitly bridges manufacturing processes, the data they generate, and the measurement and testing technologies used, fostering a holistic understanding of the technical processes and their analysis and interpretation.

The seminars (FMOF, DACOP) offer practical knowledge in using powerful open-source software for fluid simulation (OpenFOAM) as well as relevant programming languages and software tools for data collection, analysis, and optimization. These seminars are independent of the lectures and initially do not address foundry-specific issues within the introductory framework. Thus, they also offer a practical entry point into the programs and methods employed throughout your studies.

In the manufacturing technology practical course (FTP1), you actively participate in the production of aluminum cast components and perform destructive testing to characterize the parts. You will learn about the impact of various manufacturing parameters, alloys, and component geometries on the performance of cast components, while simultaneously gaining practical experience with advanced testing technologies.

Furthermore, the LGT offers supervision of theses and internships.